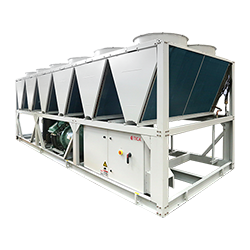

Air-Cooled Flooded Screw Chiller (Heat Pump)

Description

Energy-efficient solution, comfort and quiet, smart defrosting, cloud-based data management system.

Features

- Energy-Efficient Solution

Eco-friendly R134a, various efficiency options to meet different requirements.

Economizer is added to substantially improve cooling/heating performance. Heating COP under low temperature is improved by 15%-20%.

-Comfort and Quiet

Precise water temperature control (±0.3°C), energy provision by demand.

Low-noise axial flow fan and long type air duct diversion to effectively reduce the airflow noise.

- Reliability

Multiple safety protection technologies can ensure safe operation.

Unique smart defrosting technology guarantees efficient defrosting.

-Intelligent Control

Smart control system and cloud-based data management system for automatic control of the unit.

Technical Specification

-Patented High-Efficiency Compressor from Germany

Three-stage oil separator with efficiency up to 99.5%.

With the slide valve for stepless regulation, a single compressor can precisely match 25% – 100% load changes.

The screw rotator reaches micron-level precision.

Efficient motor with large capacity can significantly increase the EER.

-High-Efficiency Heat Exchanger

Efficient flooded-type shell-and-tube heat exchanger, super-efficient heat exchange tube, inner-threaded tube, and external fins substantially increase the heat exchange efficiency.

V-type heat exchanger is adopted at the air side, with dual-module seamless configuration.

New open-window aluminium fin greatly enhances the air turbulence and increases the heat exchanging efficiency by about 8%.

-Unit Microcomputer Control Center

Advanced pre-control function enables measures to be taken promptly before actual failure occurs to avoid frequent startup/shutdown.

Full-lifecycle cloud-based data management system provides comprehensive control and powerful big data support for customers.

-Unique Smart Defrosting Technology

Smart defrosting: Based on temperature parameters measured by the sensor, the unit can precisely determine the existence of frost by analyzing the unit operating parameters.

Minimum defrosting duration: Under national defrosting conditions, the defrosting duration is only 4.5% of the total heating duration.

Defrosting EXV control: The EXV can precisely control the opening during defrosting to avoid problems of traditional thermal expansion valve such as liquid hammer and oil shortage.